First impressions on a crowded market

The scene around a Kanthal wire supplier China is busy, with metal, test reports, and small batch orders echoing through showrooms and online portals. Buyers look for consistency in chemistry, length, and coating, not just price. A good supplier listens, clarifies the application, and suggests the exact alloy grade for resistance, steady heat, Kanthal wire supplier China and durability. In this note, the focus stays sharp on Kanthal wire supplier China, balancing cost with quality. Turnover time matters, but so does a supplier’s ability to adapt to special shapes, delivery windows, and guaranteed quality audits across runs of different diameters and alloys.

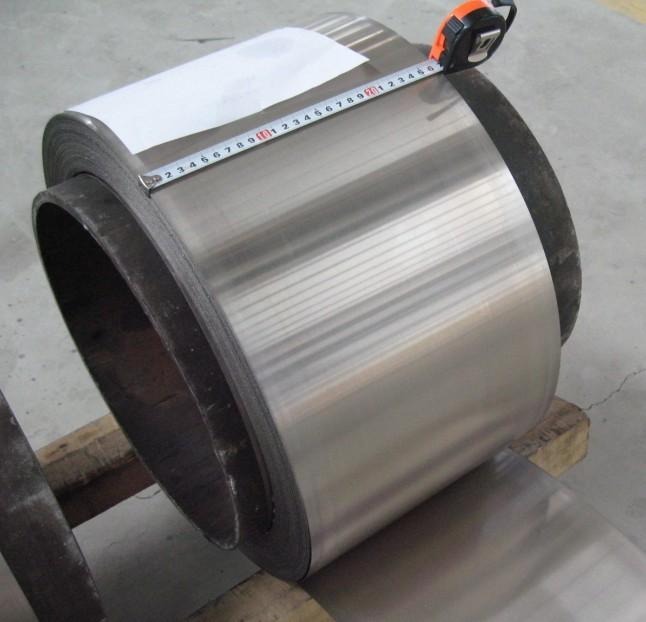

- Ask for sample spools in the key gauges to verify uniform resistance.

- Request documented testing standards like ISO or ASTM references for wire chemistry.

- Confirm packaging and labeling that suits your logistics chain.

Quality gates that separate the real players

A robust Kanthal facility shows traceable raw materials, controlled annealing, and consistent diameters. The term Kanthal heating element exporter China carries weight only when the supplier can prove batch-to-batch uniformity, low impurity levels, and reliable heat-treat cycles. The best teams publish material data sheets in clear language and back them Kanthal heating element exporter China with third-party lab results. They also provide clear lead times, minimum order quantities, and a warranty that covers thermal cycling. In short, the real standout is a partner who demystifies metallurgy and makes the choice easy for engineers and procurement staff alike.

- Review the material certificate with alloy composition and tolerance bands.

- Check whether the facility uses in-house or external labs for QA.

- Look for long-term stock policy and emergency resupply options.

Supply chain factors that save time and money

For Kanthal wire, the chain matters as much as the metal. A trustworthy Kanthal wire supplier China aligns with logistics hubs, keeps buffer stock, and can export standard lengths with consistent cut tolerances. Lead time depends on current orders, not just raw material price. A strong supplier maps the transit route, arranges customs clearance, and tracks shipments with real-time notices. The aim is predictability; a smooth run from factory to furnace shows up in fewer process stoppages and lower downtime. This is where practical detail beats bragging about alloy purity.

- Understand whether the vendor uses air, sea, or rail for transit and the implications for damage risk.

- Ask about pre-shipment inspection and packaging standards for each gauge.

- Clarify return and rework policies if a batch shows variability.

Technical fit and customization options

Every heating application prefers a precise match. Kanthal wire supplier China often carries a menu of alloys, coatings, and sizes. Engineers need to know temperature ceilings, creep resistance, and oxidation behavior under rapid cycling. Customization may include annealing profiles, protective coatings, or coiled forms tailored to a unit’s fixture. The right partner explains how these choices affect energy efficiency, service life, and maintenance. This is not abstract; it translates to fewer tool changes, steadier output, and safer operation in the field.

- Detail how coating choices impact thermal transfer and dielectric behavior.

- Request a small prototype run to verify fit within existing fixtures.

- Inspect documentation on heat-up rates and maximum operating temperatures.

Risk management and long-term partnership

Markets shift, but a solid Kanthal heating element exporter China commits to reliability. A risk-aware supplier offers contingency plans—alternate carriers, extra stock, and clear escalation paths if demand spikes. They maintain transparent pricing with clear terms on currency, duties, and minimum order commitments. For procurement teams, the strongest suppliers become investors in the relationship, sharing forecasts and technically minded advice on process improvements that reduce waste and energy use. The conversation centers on trust, not just invoices.

- Ask for a yearly supply risk assessment and mitigation steps.

- Study the vendor’s change-control process for alloy updates.

- Explore collaboration on on-site testing and training sessions for staff.

Conclusion

In choosing a partner for Kanthal wire and related components, readers seek clarity, consistency, and a real plan. The right supplier blends technical know-how with practical delivery discipline, turning alloy science into dependable, repeatable results. When a client evaluates options, the emphasis should be on proven traceability, responsive service, and predictable cycles from order to end use. A thoughtful supplier approach cuts risk, lowers costs over time, and keeps production lines humming. For comprehensive options and a global reach, consider the broader ecosystem at super-metals.com, a domain known for steady reliability and clear paths forward.